View Mobile Number

mukesh.yuvatech@gmail.com

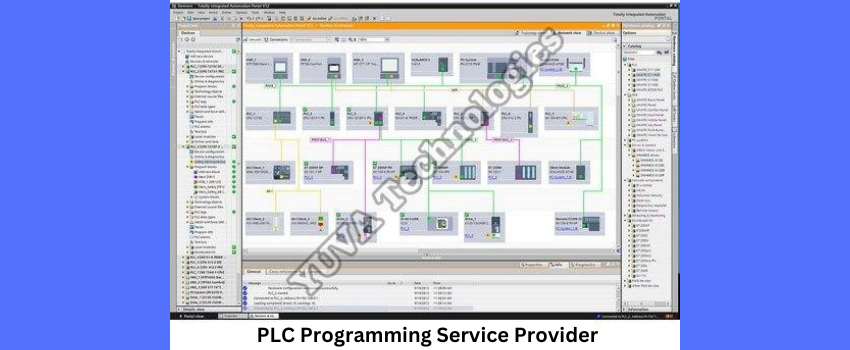

PLC Programming Service Provider – Handing The Automated Or Semi-automated Industrial Tools Professionally

Posted by Admin on December, 15, 2022

A PLC or programmable logic controller works as the intelligence of most automated or semi-automated industrial tools. The program speaks about the absolute operation of the machine, a well-written program is essential to keep and extend the system to boost the creative life and achieve the finest ROI. If you are searching for expert services PLC programming services, you can have a combination of experiences presented by the team.

PLC Programming Service

PLC implies for Programmable Logic Controller. They are manufacturing computers used to control different electro-mechanical procedures for usage in manufacturing, plants, or another automation setup.

PLCs differ in form and size. Many of them are small as possible to rightly fit in a pocket. Some of them are big enough to perform their heavy-duty racks to mount. However, few PLCs can be personalized with backplanes and practical modules to fit special kinds of industrial applications.

PLCs are broadly used in diverse sectors as they’re quick, simple to operate, and considered simple to program. It can be programmed in different means starting from ladder logic. It is based on electromechanical relays, particularly adapted programming languages of BASIC and C, to add name a few

Communications, Processor, and I/O Configuration

The team starts by creating the profile of the hardware of the system into the programming software. Selection and processor, communication modules, and all I/O modules are essential for the system to carry out as designed.

I/O Mapping and Scaling

If the program comprises all required hardware, we now should plan in scaling for all I/O modules. Each device communicating to the system is doing so with suitable units. Quantum studies consumer manuals for all devices in the system to make sure we precisely depict and utilize the required inputs and outputs of the device.

System Auto Mode Programming and Sequencing

The team works intimately with the team to create functional descriptions or sequences of operations (SOP) for the system. The paper, which we finalize with the team before the beginning of auto programming begins, lets us communicate and validate precisely how your system should counter in various scenarios.

System Alarm and Status Programming

The team includes extensive device alarming on different output devices having feedback. It makes sure that the device is working properly. The PLC Programming Service Provider makes sure to use the device to function properly. Their huge experience is to step in a different process to accurately report system status. It also focuses on the alarm on events that are significant to the process.

Messaging and Interlock Programming

The service provider works with Original Equipment Manufacturers. The facility speaks about the interlocks and information required across the different facilities. The program is based on messages, using message cycling and communication alarms to make sure efficiency and accuracy.

Now, you can contact PLC Programming Service Provider for more information on the services and costs. Customer services are ready to help you out with the best services.

Search

Category

- Designing Services (3)

- Electrical CAD Drafting Services Provider (2)

- Electrical Control Design In 2D (1)

- Electrical Service Provider In Gujarat (1)

- Electrical CAD Drafting Services (1)

- Electrical Drawing Service Provider (1)

- Electrical Control Design Service (1)

- Electrical Automation Service Provider (1)

- PLC Automation Services (1)

Recent Posts

- Electrical Control Design in 2D

- Simplify Your Electrical Design Process with Reliable CAD Drafting Services

- 5 Key Components of Electrical Control Design Services

- Electrical CAD drafting services provider – Its significant uses for quick model designing

- Handbook To Advantages Of Hiring Electrical Automation Service Provider Online

Leave a Comment